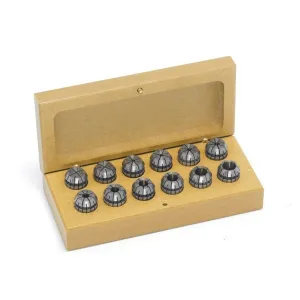

Collets and collets sets

Looking for a high-quality collet?

Do you need a collet for clamping tools on your CNC machine? Or has your collet broken and are you looking for a new one? Then Veldman Slijptechniek is the right place for you. We supply various types of collets such as the well known types ER16, ER20, ER25, ER32 and ER40 but also the less used sizes such as EOR25, ETSS40 and EOC16 we can usually supply directly from stock.

What is a collet?

A collet is a useful tool that is used to hold cutting tools and workpieces, such as drills, cutters and taps, in a milling or CNC machine extremely accurately and securely using a collet holder. Ideal for jobs where every millimeter counts. Although the tool can be held securely, a collet still provides the flexibility to quickly change tools. This makes a collet an indispensable tool for professional wood, metal and plastic machinists.

A collet is inserted into a collet holder and consists of a sleeve with an internal conical or cylindrical hole, into which the cutting tool is inserted. The collet has a clamping mechanism that holds the tool firmly in place while machining the material in the milling machine.

How does a collet work?

The functioning of a collet is based on the principle of expansion and clamping force. When the cutting tool is inserted into the holder, the collet is tightened using a wrench or a collet nut. This causes the collet to contract, clamping the tool firmly. The tapered design of the collet provides an even and powerful clamping force along the entire length of the tool, ensuring a secure and stable grip while machining material in the CNC milling machine.

Applications of collets

The versatility of a collet makes the tool suitable for a wide range of applications in different machines and industries. From lathes to milling machines, collets are used to hold drilling, milling and tapping tools during the machining process. With the ability to change tools quickly and easily, collets help improve productivity and reduce machine downtime.

Different types of collets

There are several types of collets available, each designed for specific applications and tool types. The most common collets are ER collets, which are widely used because of their accuracy, reliability and wide range of sizes. The main advantage of ER collets is that they are manufactured according to the DIN 6499 standard. As a result, all components of ER collets are standardized, making it the most popular toolholding system.

Other variants, such as ETS collets and EOC collets are specifically designed for use in specific collet holders in milling and CNC machines.

Questions about collets?

Want to know the best collet to use in your CNC milling machine? Or are you looking for a specific collet for a particular milling tool? Contact us for more information on the best collet for your project.