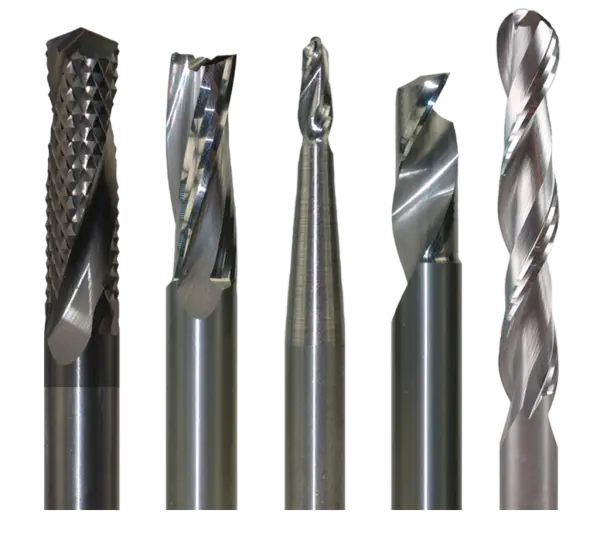

In-house production of solid carbide spiral cutters

WE CAN PRODUCE ANY SOLID CARBIDE SPIRAL CUTTER TO CUSTOMER SPECIFICATIONS

Are you working on a special project that involves machining wood, plastic or metal, for example, and a standard solid carbide end mill does not meet your needs and requirements? Then you can opt for a CNC milling cutter that is produced specifically to your wishes and requirements. Veldman Slijptechniek has specialized in the custom production of spiral cutters, among other things, for over 50 years. Based on the drawings provided by you, we can produce the tool entirely to your specifications.

Whether you need Trespa milling cutters, a staircase cutter with a small cutting length, a dibond cutter, a spiral cutter for plastic with a different shank length, a HIMACS cutter or a lockbox cutter with four cutting edges, Veldman Slijptechniek can produce it for you! Even milling cutters with cutting lengths of more than 200 mm can be supplied entirely custom-made for you. Curious about the possibilities? Then please contact us.

Tools for virtually all industries

CNC TOOLS FOR INTERIORS, CARPENTRY AND CABINETMAKING AMONG OTHERS

The tools we manufacture find their application in a wide range of industries, including the staircase industry, interior construction, carpentry, kitchen and cabinet factories, contractors, furniture makers and panel building. Our custom mills are suitable for machining plastics, aluminum, wood and sheet metal, foam, metal, copper, graphite and composite materials, among others.

Not only do we produce high-quality CNC tools, we are also experts in grinding CNC tools. In our modern grinding shop in Heerhugowaard our experienced tool grinders have access to the latest CNC machines for grinding carbide circular saw blades, among other things. This enables us to grind and produce tools 24 hours a day with the great advantage of shorter delivery times. Our modern machines also give our grinding shop the ability to grind saw blades up to a diameter of 1.35 meters.

Coating for spiral cutters

BENEFIT FROM A LONGER TOOL LIFE

If you are having a special milling cutter custom manufactured, you naturally want it to last as long as possible. We can ensure that your milling cutter or drill is provided with a special coating that can extend the tool's life. The coating of tools not only has the advantage that the milling cutter or drill will last longer, it also increases the cutting speed and the machining time of the material is reduced.

We can provide both existing and new tools with the right type of coating. Contact us for more information on tool coating or request a no-obligation quote.

Single cutter or small production run

Whether it is just one solid carbide spiral cutter or the production of a small run of cutters, in our modern grinding shop we are able to produce almost any custom cutter for you. Are you interested in producing a custom milling cutter or would you first like to receive more information about the possibilities for producing specific milling cutters in small quantities? Then please contact us.

Because we always have a large amount of basic material in stock at our grinding shop in North Holland, we can produce customer-specific cutters at very short notice. So you never have to wait long for your CNC tools and you can quickly continue with the completion of your project!